Production of Medium & Heavy Vehicles

-

Stronger emission regulations in the European Union and the US induce a reduced fuel consumption

-

This stimulates investments in a new generation of trucks and commercial vehicles

Mechanical Engineering: Slight Recovery in Europe, Growth in Asia

-

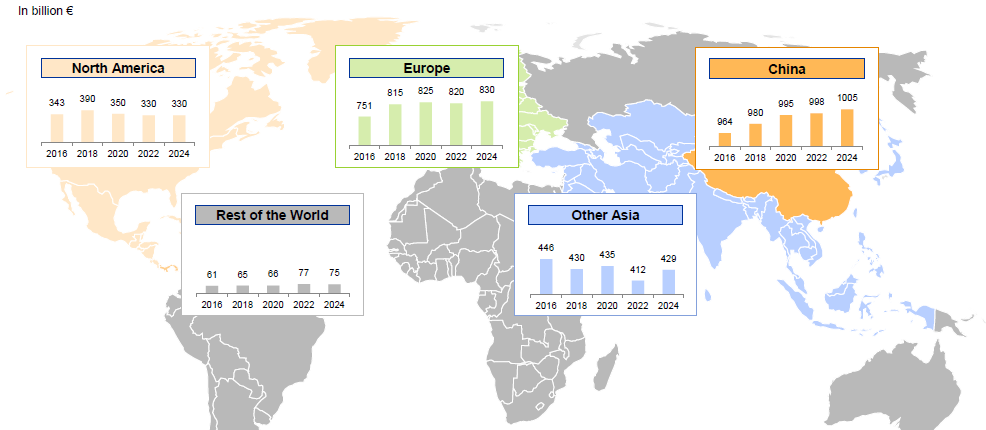

Globally, we expect further increases in demand for mechanical engineering products

-

Sales in China will show a further growth within the next years. Chinese sales will be higher than the combined sales of the rest of Asia and North America

-

In Europe, Germany and Italy will gain market share compared to other western European states

-

In the mechanical engineering industry there is a movement towards lightweight construction (robotics, machine tools, etc.)

Global Aluminum Cast Production will strengthen

-

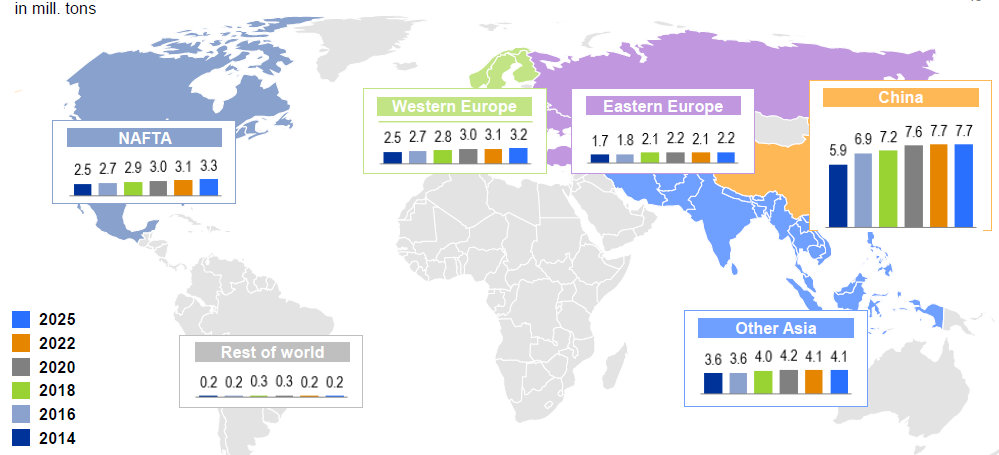

The trend towards electrical vehicles and light-weight production induces a rising aluminum foundry production

-

In addition to the higher production volume in Western Europe some of the leading foundry groups invest in Eastern Europe, too. We see a recovery in Russia and Ukraine and a catching-up process in Turkey

-

The majority of growth in the NAFTA region will be fueled by investments of foreign OEMs and global foundry groups

-

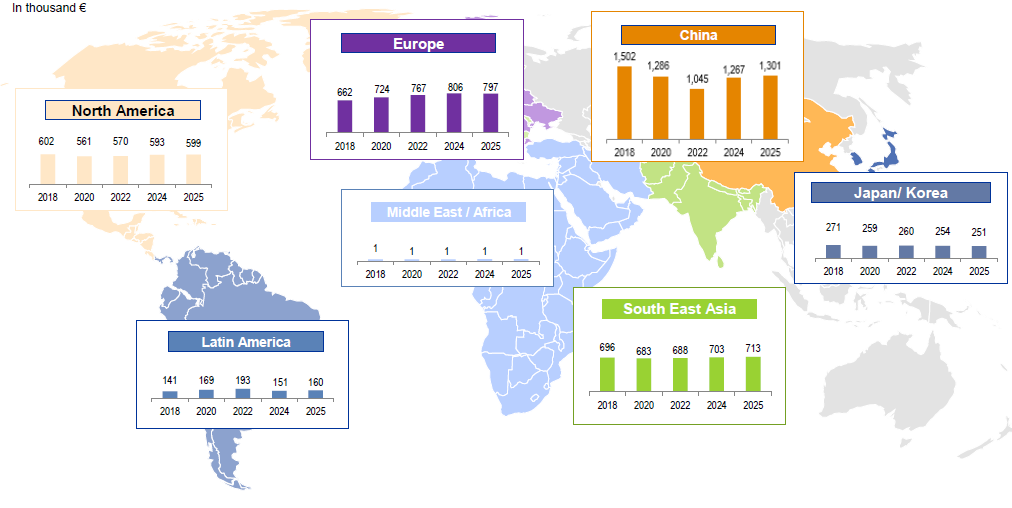

Korea and Japan will lose market shares to China

ABOUT KEVA

Keva Casting is a professional casting company that focuses on Construction, Machinery, Automobile, Hardware, Pipeline and many other industries.

We provide top quality products with the best service based on our complete production chain including our own mold design, advanced production techniques, and full management of the supply chain. Keva Casting has two factories located in Zhucheng, China's Shandong province.

We use "shell molding", which is a new technique that has been developed in recent years.This new technique has simplified production procedures and reduced air pollution compared with traditional sand casting and investment casting. Shell making and core making are faster to ensure production in enormous quantities. The dimensions and surface finishing are satisfactory for all kinds of industrial requirements. Besides supplying our own formwork & scaffolding systems, our casting products also supply OEM services in various industries.